Your cart is currently empty!

ISO 10993-18: Medical Device Extractables Leachables Testing Using Chemical Characterization

Why Companies Choose NAMSA

Medical Device Tests Run Annually

Test Results Delivered On-Time

Chemical Characterization Tests Conducted Last Year

Major Labs in the US and EU Performing ISO 10993 Testing

World Leader in ISO 10993-18 Lab Testing

Extractables and Leachables (E&L) testing is a crucial process in the evaluation of medical devices NAMSA was the first CRO to start performing chemical characterization on medical device materials and helped develop the standards in use today. NAMSA provides state of the art testing for chemical characterization of medical devices with two Centers of Excellence in the US and Germany. We will work closely with you through the entire journey including study design, testing, and regulatory support.

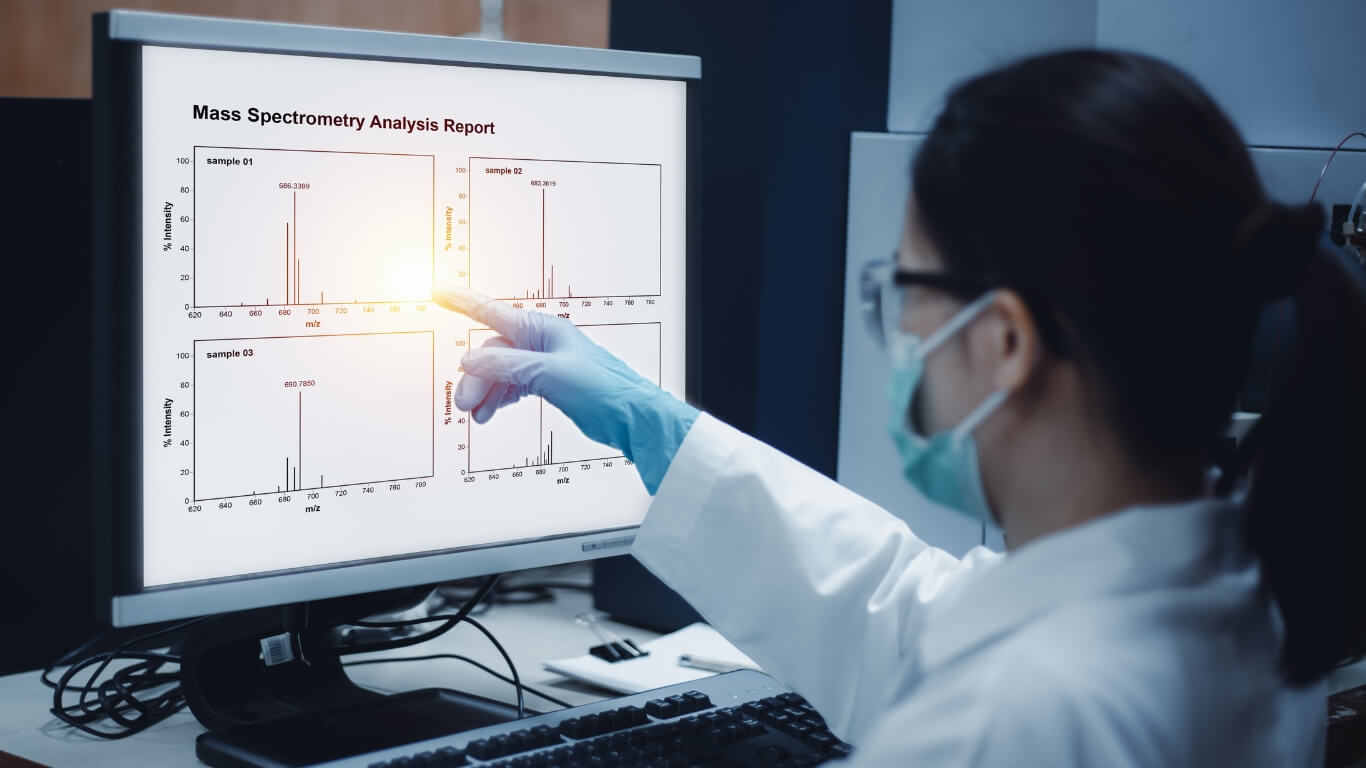

Numerous Techniques and Lab Equipment for Conducting Chemical Characterization

NAMSA labs in the US and Europe conduct thousands of chemical characterization tests on medical device materials each year. NAMSA test results are widely accepted by regulatory authorities worldwide. Our chemical characterization capabilities include, but are not limited to:

- Differential Scanning Calorimetry (DSC)

- Fourier Transform Infrared Spectroscopy (FTIR)

- Gas Chromatography-Mass Spectrometry (GC-MS) for Semi-Volatiles

- Headspace Gas Chromatography-Mass Spectrometry (HS-GC-MS) for Volatiles

- Inductively Coupled-Plasma Optical Emission Spectroscopy (ICP-OES) for Inorganics/Metals

- Inductively Coupled-Plasma Mass Spectroscopy (ICP-MS) for Inorganics/Metals

- Ion Chromatography (IC) for dissolved ions

- Liquid Chromatography-UV/VIS Spectroscopy for Non-Volatiles

What is the Difference Between Extractables and Leachables?

- Extractables are chemical substances that can be released from a medical device or its materials when exposed to solvents under laboratory conditions. This testing simulates the worst-case scenario to identify potential risks.

- Leachables are substances that may migrate from the device into the patient during normal use. Leachables testing is performed under conditions that mimic the clinical use of the device.

When and Why Chemical Characterization is Conducted

The purpose of chemical characterization is to ensure:

- Biocompatibility

- Patient safety

- Ongoing quality assurance

- Regulatory compliance

- Appropriate long-term material selection

ISO 10993-18 is the primary standard focused on chemical characterization and outlines the methods for identifying and quantifying chemical substances that can be extracted from medical device materials. This standard works in conjunction with other standards such as ISO 10993-17 (allowable limits for leachables) and ISO 10993-1 (biological evaluation). This testing is typically conducted during:

- Product development when materials are being selected

- Preclinical testing, before clinical trials

- Manufacturing validation to ensure no production methods introduce hazardous leachables into final product

- Supplier changes to evaluate new raw materials or finished components

- Post-market monitoring via PMCF studies

These test results are one step in the process of ensuring the ongoing safety of your device and become a vital part of your technical documentation, especially your risk management file.

Meet Our Chemical Characterization Testing Team

Explore the depth of our team’s expertise in E&L testing on medical device materials.

-

Alexander Hermann, PhD

Supervisor, Study Director GroupView Bio

Supervisor, Study Director GroupView Bio -

Angela Sanchez

Associate Scientific Director, Analytical ServicesView Bio

Associate Scientific Director, Analytical ServicesView Bio -

Darin R. Kent, PhD, DABT

Senior Principal ToxicologistView Bio

Senior Principal ToxicologistView Bio -

Gabriele Bellandi, MSc

Director of German Laboratory OperationsView Bio

Director of German Laboratory OperationsView Bio -

Tim Petermann

Principal ChemistView Bio

Principal ChemistView Bio -

Andy J. Wyen, MS, DABT, LAT

Principal ToxicologistView Bio

Principal ToxicologistView Bio

Commonly Asked Questions About Our ISO 10993-18 Testing Capabilities

ISO 10993 is a series of standards published by the International Organization for Standardization (ISO) that covers the process for evaluating the biocompatibility of medical devices to manage biological risk.

The official title: ISO 10993-18:2020: “Biological evaluation of medical devices — Part 18: Chemical characterization of medical device materials within a risk management process”

There are generally three critical elements evaluating biological risks; 1) complete chemical information/chemical characterization, 2) toxicological risk assessment, and 3) biocompatibility testing. Chemical characterization is the starting point that feeds into toxicological risk assessments, as the combination of these two steps often addresses several biocompatibility endpoints. Biocompatibility testing should be used to help meet the necessary endpoints that cannot or could not be addressed in the chemistry and risk assessment.

Part 18, provides guidance on chemical characterization testing requirements and exposure dose estimation, ultimately helping the chemist gather the information necessary to design a study that will be appropriate for the toxicological risk assessment. Regulatory bodies in the US and EU have incrementally interpreted, adopted, and implemented ISO 10993-18:2020. While the FDA stopped short of full recognition, it does expect manufacturers submitting products for use in the U.S. to address the requirements of the standard. MDR has accepted the standard as “state of the art” and generally holds manufacturers to it.

The best way to meet expectations is to stay current with regulatory updates. Our technical and regulatory experts serve as active participants and hold leadership positions within international regulatory standards committees. This allows us to better anticipate regulatory changes ahead of the published standards and guidance and track regulatory trends. We guide our clients’ test plans based on our industry knowledge, regulatory collaboration, and the extensive number of products we have assisted through product clearance.

Chemical characterization, also referred to as materials characterization, should be designed with the nature and duration of clinical exposure in mind. Chemical information can be a paper-based review of all materials or chemical data can be generated in a screen for all potential extractables/leachables or a targeted study focusing on a single compound of concern. However, extractables/leachables (E/L) testing is often necessary due to the risk of impurities in the raw materials and hazardous chemicals being introduced into the medical device during routine activity such as manufacturing, sterilization, and storage.

Chemical characterization of a medical device is the first step in the biological evaluation process, which means you should care about ISO 10993-18 early on in the preclinical testing process. But it must be completed on the finished medical device as part of the regulatory submission package. This gives chemists and toxicologists the full picture, including manufacturing and sterilization methods that might impact the extractables profile of the product.

Chemical characterization should be considered a journey, not a check-box exercise.

For many medical devices, exhaustive and exaggerated extractions are recommended by ISO 10993-18:2020 and are expected by regulators.

Extractables study designs challenge devices under extreme conditions to maximize the extraction of chemicals from the devices and provide information for estimating potential hazards. Exhaustive extraction studies involve extracting devices in solvents with ranges of polarity and repeating the extractions until the amount of extractable material in subsequent extractions is less than 10 percent by gravimetric analysis of that detected in the initial extractions. The intent of extractables studies is to determine the cumulative amounts of each chemical that could potentially extract from devices over time. Exaggerated extractions may be the appropriate method to maximize extractable chemicals that could be released from limited and some prolonged duration devices. Exaggerated extractions also use aggressive solvents and elevated temperatures to yield extractions.

Leachables/simulated-use study designs may be conducted to evaluate the potential for chemicals to extract or leach from devices under clinically relevant conditions. These studies incorporate the actual clinical matrix (leachable study) or a solvent that simulates the environment of clinical use (simulated-use studies).

Because TRAs based on exhaustive extractions often require additional chemical characterization studies (e.g., leachables or simulated-use) to further refine exposure assessments and mitigate risk, it may be helpful from a timeline perspective to conduct both studies concurrently. Otherwise, the studies can be conducted sequentially with the understanding that longer timelines may be necessary to conduct a complete toxicological assessment of the device.

This process of chemical identification is laborious and requires investment in equipment, expert personnel, and the time commitment to complete identification.

Yes. Instrument redundancy is available at both sites for all key analytical platforms to ensure there is ample capacity to reduce turnaround times. This also allows our clients to conduct their programs seamlessly at either of the two global sites. Expedited testing options are available at both sites to give clients the option to receive their testing results sooner if there is a need.

NAMSA has made significant improvements in reducing the “unknowns” identified during non volatile testing of extracts. Unknowns are less than 1% for all peaks. NAMSA has extensive experience in interpretation and identification of analytes with significant investments made in training and external tools to enhance our interpretation confidence. The lab has established an extensive library covering a wide range of compounds spanning a range of medical devices.

NAMSA has extensive experience working with regulatory bodies have have several team members who previously worked at the US FDA. We will work closely with you after your program is complete to answer questions after submission of data to a regulatory body. This includes joining you in direct discussions with regulatory authorities.

In 2024, the US FDA unveiled a Chemicals List for Analytical Performance (CLAP) dataset designed to help assist chemistry labs in ensuring the robustness of chemical characterization methods used to assess the biocompatibility of medical devices. The CLAP data set was specific to semi-volatile organic compound (SVOC) extractables data. NAMSA has evaluated FDA CLAP dataset and determined that there is a significant overlap of recommended compounds between CLAP and our internal database. We have been working on building our internal RRF database for all techniques over the past 5 years with chemical compounds covering a variety of chemicals.

Other Testing Services That May Interest You

Biocompatibility Testing

Microbiology Testing